A Powell lens, often referred to as a laser line-generating lens, plays a critical role in shaping collimated laser beams into straight, uniform lines. This lens expands light in a single dimension and features an acylindrical surface at its apex, which helps distribute optical power evenly across the beam. Unlike conventional cylindrical lenses, Powell lenses are designed to eliminate the “hot spot” in the center of the beam, creating a more consistent intensity across the laser line.

Powell Lens

Lasers are ubiquitous in many modern industries, from communications and medical devices to laser printing and lighting. However, for specific applications, laser beams often need to be modified or shaped. Powell lenses serve as a key tool for this purpose, transforming circular laser spots into linear ones while evenly distributing the light intensity. This process smooths out the typical Gaussian distribution of light, producing what’s known as a flat-top beam with uniform energy across the output.

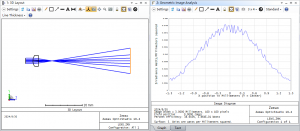

Powell lenses differ from standard cylindrical lenses in their design. These lenses feature an aspherical surface in one direction, while the perpendicular direction remains flat. Light passing through the lens converges and spreads in a single direction while maintaining the same spot length in the other. This redistribution of light results in a much more uniform beam than what can be achieved with a standard cylindrical lens, which tends to produce a beam with an intense center and weaker edges.

Powell Lens

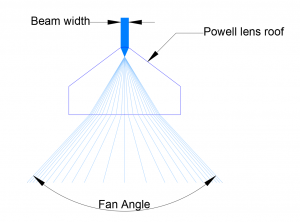

Two major factors influence how Powell lenses are designed and used: fan angle and incident spot size.

Fan Angle of Powell Prism

Powell lenses find utility in a variety of fields, particularly in scenarios where precise laser shaping is needed. Common uses include:

When choosing a Powell lens for a particular application, it’s essential to consider the lens’s fan angle and the laser beam’s incident spot size. The fan angle is determined by the lens’s apex, or roof, curvature and the material’s refractive index. It’s crucial to match the lens curvature with the beam width to achieve optimal results.

The manufacturing quality of a Powell lens also plays a significant role in its effectiveness. Any imperfections in the lens can lead to deviations in the laser line’s straightness or aperture, reducing its precision. Therefore, high-quality construction is necessary for applications that demand tight tolerances.

Powell lenses provide several benefits over standard cylindrical lenses:

In summary, Powell lenses are essential optical components that allow for precise laser beam shaping and redistribution of light intensity. Their ability to create uniform, straight laser lines makes them indispensable in industries like laser communication, medical devices, manufacturing, and more. By eliminating uneven light distribution and hot spots, Powell lenses enhance the performance and accuracy of laser-based systems. As advancements in technology continue, these lenses will remain a crucial tool for applications that demand both precision and reliability.

Contact Shanghai Optics today! We’d be more than happy to discuss your projects and how to best bring them to fruition.