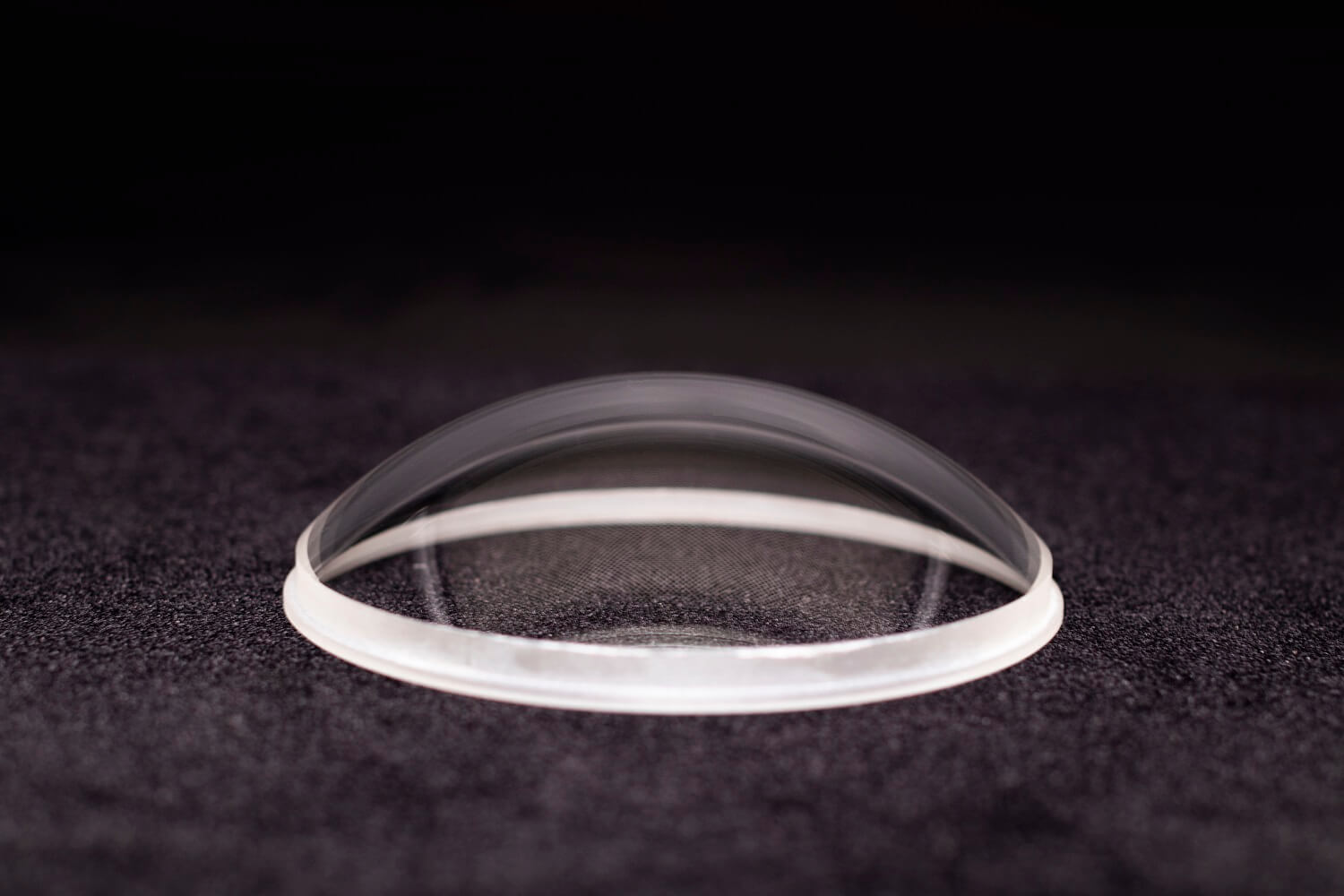

At Shanghai Optics, we specialize in custom optical glass domes designed to meet the demands of various industries. Optical domes are hemispheric windows that provide a protective boundary while allowing a clear field of view between two environments. They are typically made with two parallel surfaces. Shanghai Optics manufactures optical domes in a wide variety of substrates, suitable for visible, IR, or UV light. Our domes are available in sizes ranging from 5 mm to over 200 mm diameter, with custom sizes available upon request.

We can also manufacture acrylic domes on request. These domes offer less light scattering than BK7 or fused silica, and are still highly durable.

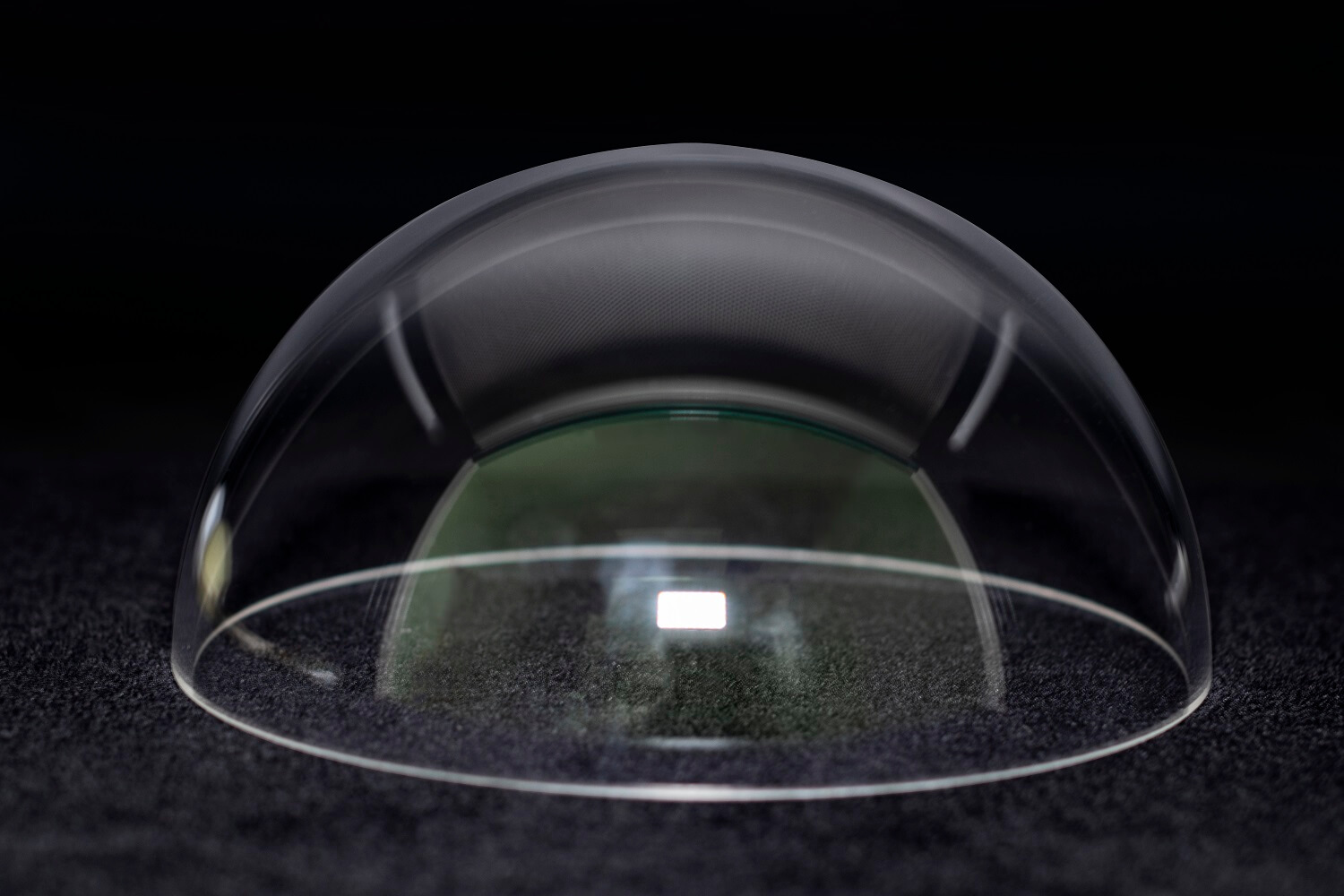

Germanium Dome Lenses – Diameter: 187.3mm / Height: 60mm

| Material: | BK7, CaF2, Cleartran, Fused Silica, MgF2, etc |

| Diameter: | 2~500mm |

| Thickness: | >1mm |

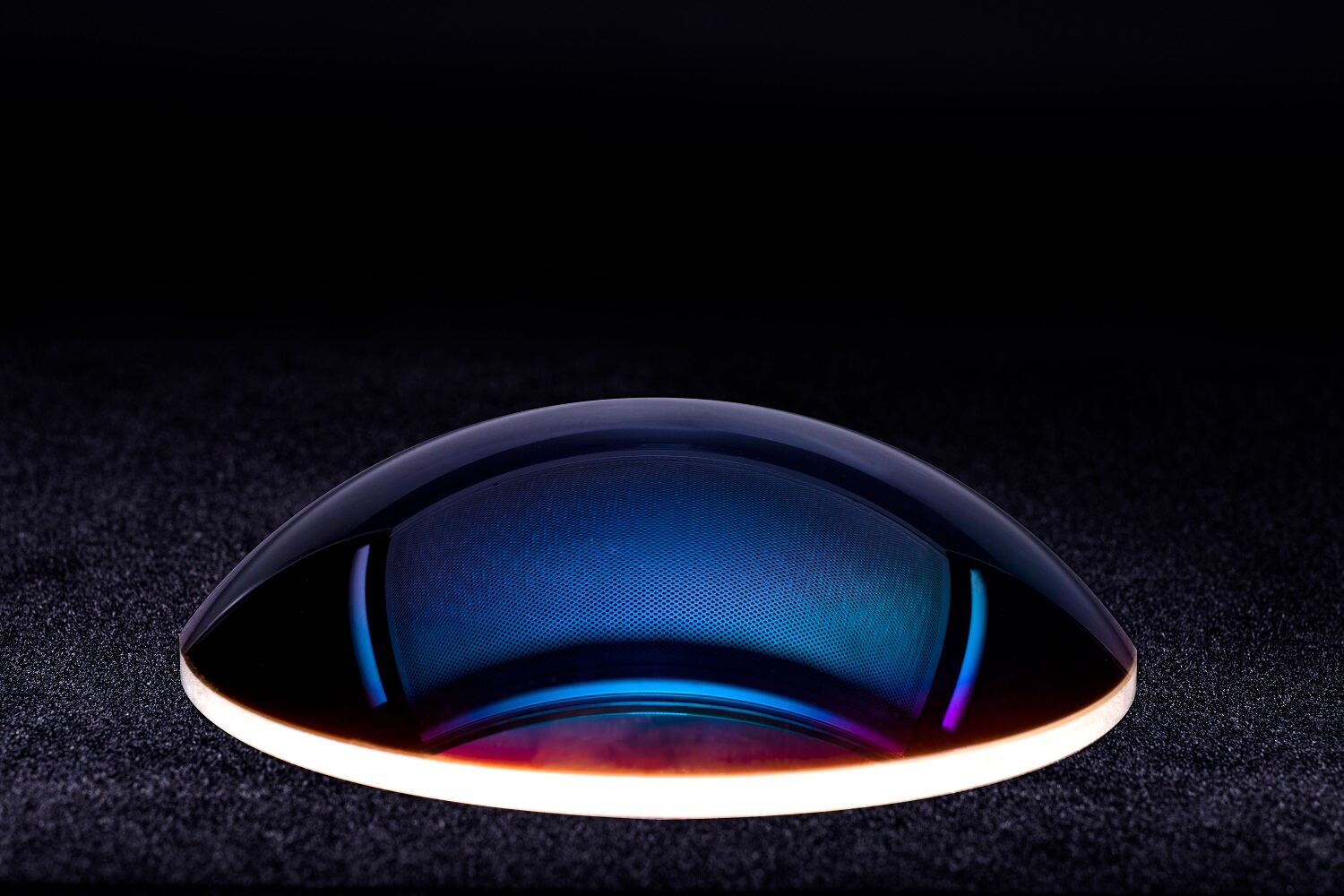

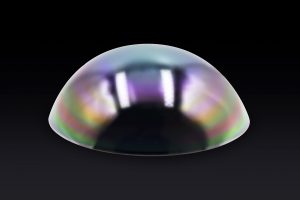

| Coating: | AR coating for VIS, SWIR, NIR, MWIR, LWIR, broadband |

| Surface Accuracy: | 1/10-1 lambda |

| Dimensional Tolerance: | +/-0.1mm |

| Scratch & Dig: | 20/10-60/40 |

| C-A: | 90% |

| Environment Testing: | Extreme cold-heat cycle, sand blasting, salt water, adhesive test |

| Specification Testing: | Qualification Test, Optimization Test, Dimensional Test, According to DIN, ISO and MIL standards |

Our high quality optical domes, made from durable materials like sapphire and MgF2, offer superior protection and optical clarity in challenging environments. Whether you need domes for aerospace LIDAR sensors, underwater imaging systems, or infrared defense applications, we provide tailored solutions to ensure optimal performance. These hemispheric high quality optics are essential for safeguarding sensitive systems in high-pressure, high-impact conditions, from deep-sea ROVs to weather monitoring and security technology.

Shanghai Optics’s expertise ensures your optical domes deliver precision, durability, and unmatched protection. To learn how we can assist with your current optics project, request a quote online or contact one of our friendly representatives for more information.

CVD Zinc Sulfide Dome φ151.8mm CVD Zinc Sulfide Dome φ151.8mm |

CVD Zinc Sulfide Dome φ218mm CVD Zinc Sulfide Dome φ218mm |

Fused Silica Optical Dome φ 120mm Fused Silica Optical Dome φ 120mm |

MgF2 Dome 100mm.jpg) Hot Isostatic Pressing(HIP) MgF2 Missile Dome 100mm Hot Isostatic Pressing(HIP) MgF2 Missile Dome 100mm |

Zinc Sulfide Dome 120 mm.jpg) Fused Silica Optical Dome φ 120mm |

Zinc Sulfide Dome 141mm.jpg) Hot Isostatic Pressing(HIP) Zinc Sulfide Dome φ141mm |

MgF2 Optical Dome φ224mm |

N-BK7 Glass Dome φ185mm |

Polycrystalline Zinc Sulfide Dome φ120.4mm |

Germanium Dome φ187mm |

H-K9L Dome with longpass hydrophobic coating φ114mm |

Germanium Dome φ187.3mm |