An off axis parabolic mirror is an optical device which transforms plane waves into spherical waves and spherical waves into plane waves. This makes it useful for collimating light from a point source as well as focusing collimated light to a point. It does this with high accuracy, and is not dependent on wavelength. Shanghai Optics high quality off-axis parabolic mirrors can be used in broadband UV, visible, and IR applications.

A parabolic mirror is a reflector in the shape of a circular paraboloid. Typically made of a highly reflective material such as aluminum, a standard parabolic mirror will center on the vertex of the paraboloid. This is the point where the curvature is greatest, and where the paraboloid is symmetrically divided by its axis. Parabolic mirrors are effective at collecting collimating light and focusing this light to a point, but the receiver will often cast s shadow on the paraboloid’s vertex. This blocks a significant part of the mirror from reflecting light, resulting in substantial signal loss.

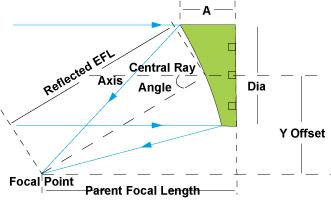

Off-axis parabolic mirrors are designed to eliminate this problem. These mirrors are sections of a parent paraboloid that are taken from a point other than the center axis. Depending on how far away from the axis the section originates, an off-axis parabolic mirror may feature a large or a small angle. But since these mirrors focus light to offset points, outside the collection area, there is no issue with receiver shadowing. This makes off-axis parabolic mirrors the optic of choice for long-range and precision instrumentation. The unrestricted access these mirrors give to the system’s focal point also leads to compact system designs.

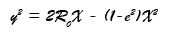

The following factors are also very useful in determining the performance of OAP Mirror:

For enhanced performance, our mirrors can be coated with a protected aluminium layer, providing durability and improved reflectivity across various wavelengths. Various reflective coatings can be applied to our mirrors, tailored to different spectral regions and application needs.

Coating Options include:

OAP mirrors are beneficial in minimizing chromatic aberration since they focus all wavelengths at a single point, enhancing image clarity and accuracy.

Our OAP mirrors are diamond turned, a process that ensures high precision and surface quality, critical for demanding optical applications.

Each mirror has a flat back equipped with three threaded mounting holes for secure attachment. Typically, an adaptor plate is placed between the OAP back surface and a kinematic mirror mount. Given that off-axis mirrors are not rotationally symmetric, rotation around the optical axis must be restricted. Precision machined mounts are recommended for sensitive alignment of the six degrees of freedom.

Our OAP metal mirrors are used in spectrometers, interferometers, astronomical optical instruments, spectrum analyzers, and in beam expanders and beam collimators. They can be used in sequence to create a relay system, since with multiple mirrors you can switch between focal plane and pupil plane of your system without degradation in image quality.

Off axis parabolic mirrors should only be used at infinite conjugates. They can produce a perfectly collimated beam from a spherical wave, or diffraction limited imaging when focusing a collimated beam, but when they’re used at finite conjugates the image quality will be abysmal.

While using OAPs it is also important to remember that the orientation matters. If a collimated beam is incident upon the off axis mirror from an off-axis focal angle, it will not produce a diffraction limited image. If a spherical wave enters on axis, it won’t produce a collimated beam either.

Manufacturers can produce off-axis parabolic mirrors in several ways. One method involves using a rotating furnace to form the mirrors from a molten base material. A simpler way is to cut and shape the off-axis paraboloids from metal blanks. At Shanghai Optics, we use the latter method to produce high-quality standard and custom OAP mirrors quickly.

To provide the best results, we hand-polish our parabolic mirrors from large aluminum blanks and finish them to an accuracy of 1/20 lambda RMS. Our standard mirrors come in diameters between 2.5 and 10 inches and curvatures 15, 30, 45 and 60 degrees off-axis. We also provide off-axis parabolic mirrors in custom sizes and coatings upon request, so you can find an OAP mirror to meet your exact project requirements.

Off-Axis Parabolic Mirror

An OAP mirror can harness collimated light by positioning a point source or spherical wave at its focal point. Similarly, it can concentrate collimated light to a specific point by directing the light along the optical axis.

Contact us for manufacturing limit or custom specifications

| Specifications | Dimension | |

| Material | Aluminum | |

| Diameter tolerance | +0, -0.2 mm | |

| Focal length tolerance | +/- 1 % | |

| +6, -0 mm | ||

| Surface accuracy | 1/10 lambda RMS | |

| Surface quality | 60-40 | |

| Note | Optics design available upon request |

| Specification | Dimension | Part Number | |||

| OAPM-15-10 | OAPM-30-20 | OAPM-45-10 | OAPM-60-20 | ||

| Type | 15° Off-Axis | 30° Off-Axis | 45° Off-Axis | 60° Off-Axis | |

| Diameter | mm | 25.4 | 50.80 | 25.4 | 50.8 |

| Effective Focal Length EFL | mm | 387.60 | 54.45 | 148.79 | 135.45 |

| Y Offset | mm | 3.95 | 27.20 | 4.14 | 4.62 |

| Note | other size and custom coating are available upon request | ||||

| Part Number | Focal Length | Diameter, D | Thickness, Te | Off-axis distance, | Off-axis angle | |

| (m) | (Inches) | (mm) | (mm) | OAD(mm) | degrees | |

| 0.5 | 2.5 | 63.5 | 15 | 60 | 6.9 | |

| 0.75 | 3 | 76.2 | 15 | 80 | 6.1 | |

| 1 | 2.5 | 63.5 | 5 | 60 | 3.4 | |

| 1 | 4 | 101.6 | 17 | 110 | 6.3 | |

| 1.25 | 3 | 76.2 | 15 | 80 | 3.7 | |

| 1.25 | 5 | 127 | 20 | 100 | 4.6 | |

| 1.5 | 6 | 152.4 | 25 | 100 | 3.8 | |

| 2 | 4 | 101.6 | 17 | 110 | 3.2 | |

| 2 | 5 | 127 | 20 | 100 | 2.9 | |

| 2 | 8 | 203.2 | 33 | 150 | 4.3 | |

| 2.5 | 10 | 254 | 45 | 175 | 4 | |

| 3 | 6 | 152.4 | 25 | 100 | 1.9 | |

| 4 | 8 | 203.2 | 33 | 150 | 2.2 | |

| 5 | 10 | 254 | 42 | 175 | 2 | |

The flat back of each of our OAP mirrors is equipped with three threaded holes for mounting. Typically an adaptor plate will be placed between the OAP back surface and a kinematic mirror mount.

Since off axis mirrors are not rotationally symmetric, rotation must be restricted around the optical axis. We recommend using a precision machined mount since alignment of the other six degrees of freedom is very sensitive.

To align your off axis parabolic mirror to collimate a spherical wave, follow these steps:

Shanghai Optics manufactures off axis parabolic metal mirrors in curvatures of 15°, 30°, 45°, and 60° off-Axis options. Our standard mirrors are manufactured from high quality aluminum, and come in diameters between 2.5 and 10 inches. Our mirrors are hand polished to an accuracy of 1/20 lambda RMS.

We are also able to provide off-axis parabolic mirrors in custom sizes and coatings upon request, so you can find an OAP mirror to meet your exact project requirements.

Possible coatings include:

Our optical engineers are available to provide off-axis parabolic mirror consulting and can help you design and produce a mirror that best matches your application. Feel free to contact us with a request for a quote, or for more information on custom options.

Request a quote online today or contact an S.O. representative to learn more about our custom off-axis parabolic mirrors and other optical manufacturing capabilities.