A dichroic mirror, also known as a dual-band mirror, dual-wavelength mirror, or dichroic reflector, is a specialized mirror which has different optical properties at two different wavelengths. For instance, a dichroic mirror might be reflective below a cut-on wavelength, then transmissive at longer wavelengths. These mirrors can be used to separate light by wavelength, and they play an important role in many optical devices. At Shanghai Optics, we manufacture premium quality dichroic mirrors for a variety of applications.

Dichroic mirrors are classified by the way in which they transmit light. Types of dichroic mirrors include longpass dichroic mirrors, shortpass dichroic mirrors, and multi band dichroic mirrors. Hot and cold mirrors used to reflect or otherwise suppress unwanted heat in thermal sensitive applications are also dichroic mirrors.

Longpass dichroic mirrors will have a cut-on wavelength that separates a highly reflective and transmissive band. Longer wavelengths, above the cut on wavelength, are freely transmitted through the mirror, while shorter wavelengths are reflected back.

A shortpass dichroic mirror features a cut-off wavelength. Radiation above the cut-off wavelength experiences high reflectance, while radiation below the cut-off wavelength is transmitted.

Multi-band dichroic mirrors have both a cut-off and cut-on wavelength, and two transmission bands as well as one reflective band. The wavelength range between the cut-off and cut-on wavelength is highly reflective, while wavelength ranges above the cut-on and below the cut-off wavelengths are highly transmissive.

Most dichroic mirrors are a type of dielectric mirror, composed of a series of layers with different optical properties. These mirrors are manufactured using electron beam deposition, ion beam sputtering (IBS) and ion-assisted deposition (IAD). State-of-the-art thin film deposition techniques allow us to ensure each dichroic mirror produced at our factory meets the exact specifications necessary to the application for which it is produced.

The hard dielectric coatings used in our dichroic mirrors make them uniquely durable, and they can be handled like glass. Our dichroic mirrors are built to withstand even high power lasers and are thermally stable under normal conditions.

Like any other dielectric mirror, the reflectance spectrum of a dichroic mirror is dependent on the angle of incidence of light. Our mirrors are typically designed for use at a 45 degree angle of incidence; if your application does not allow for this, please contact us with your specifications and to discuss the manufacture of a custom mirror.

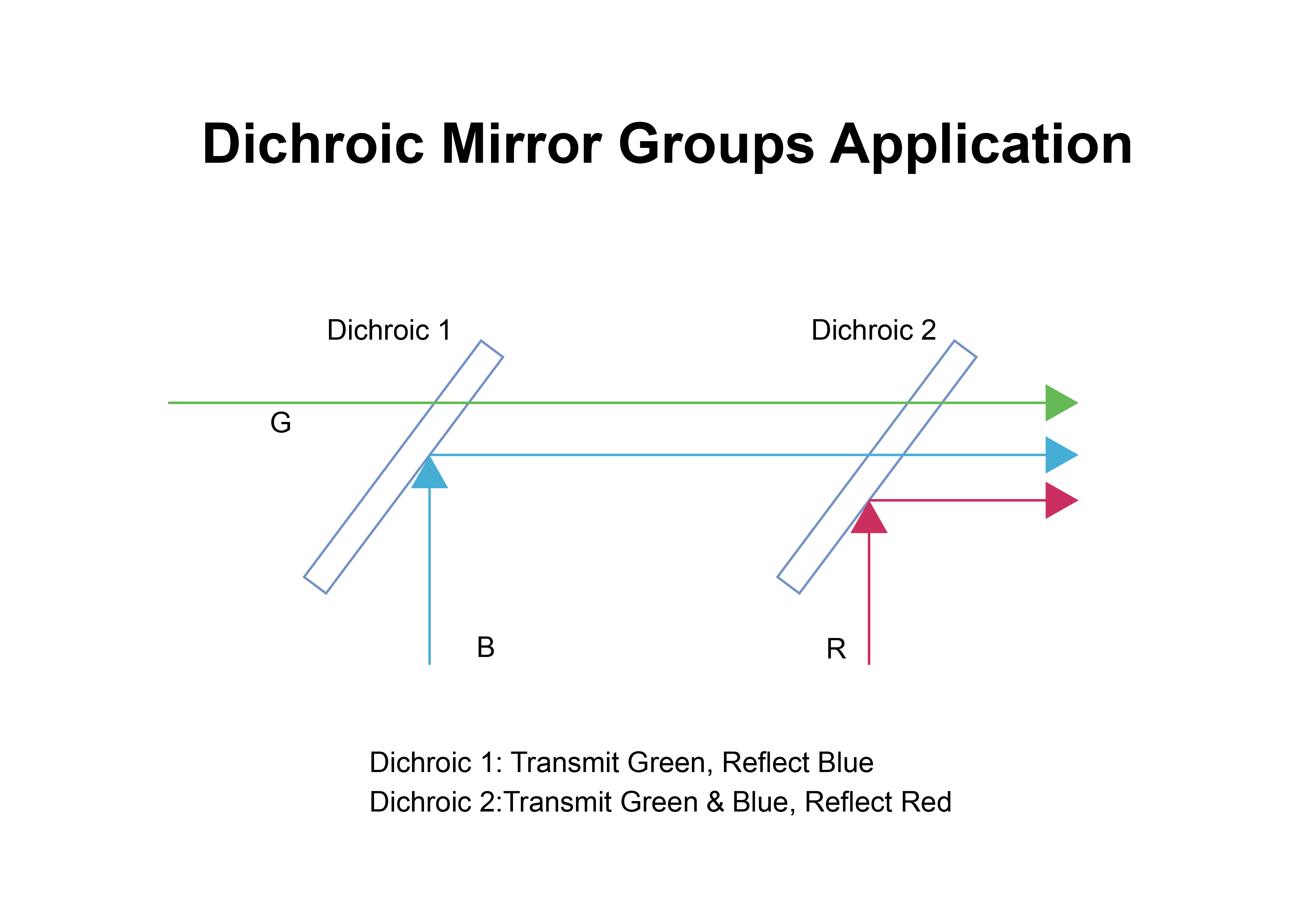

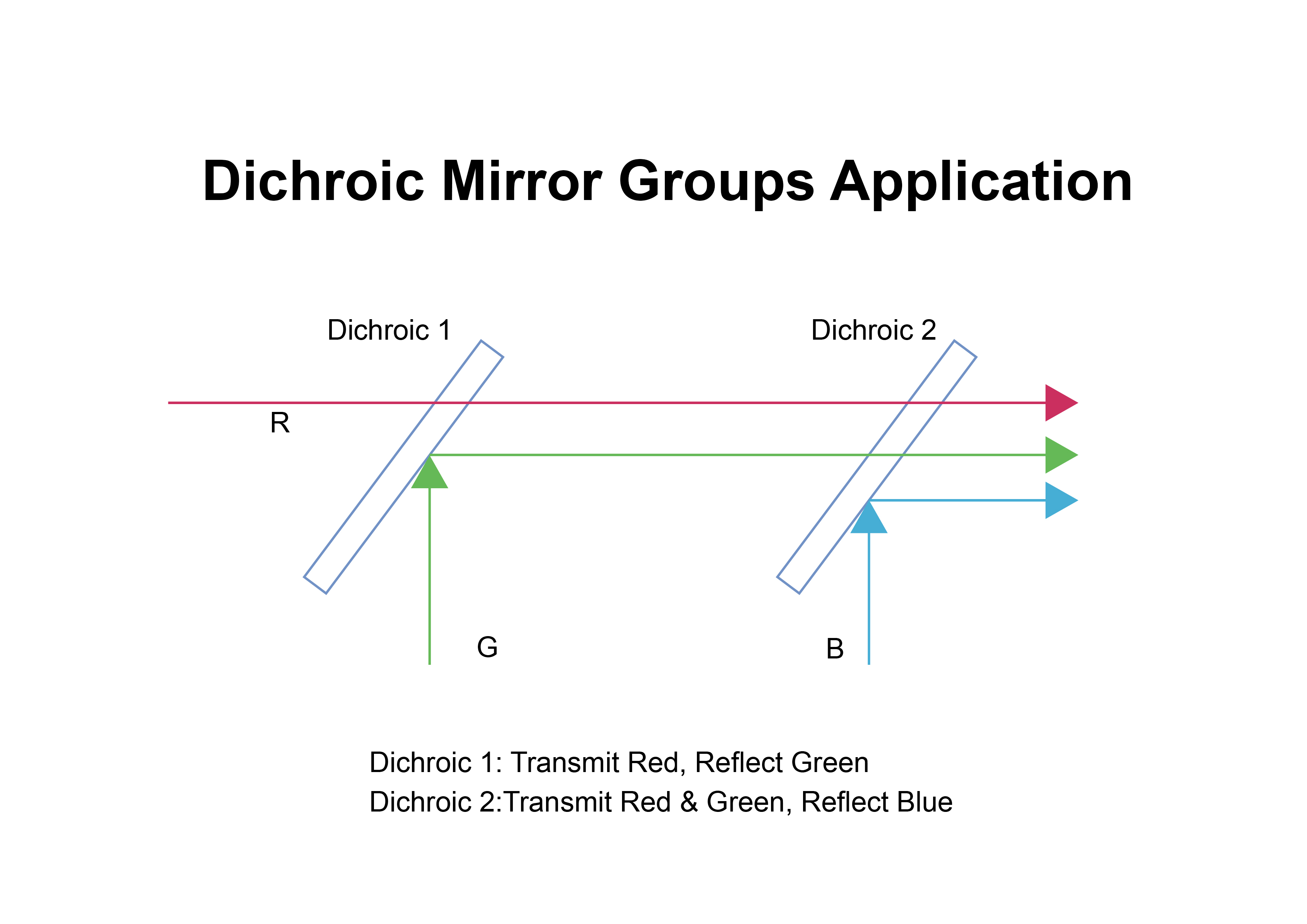

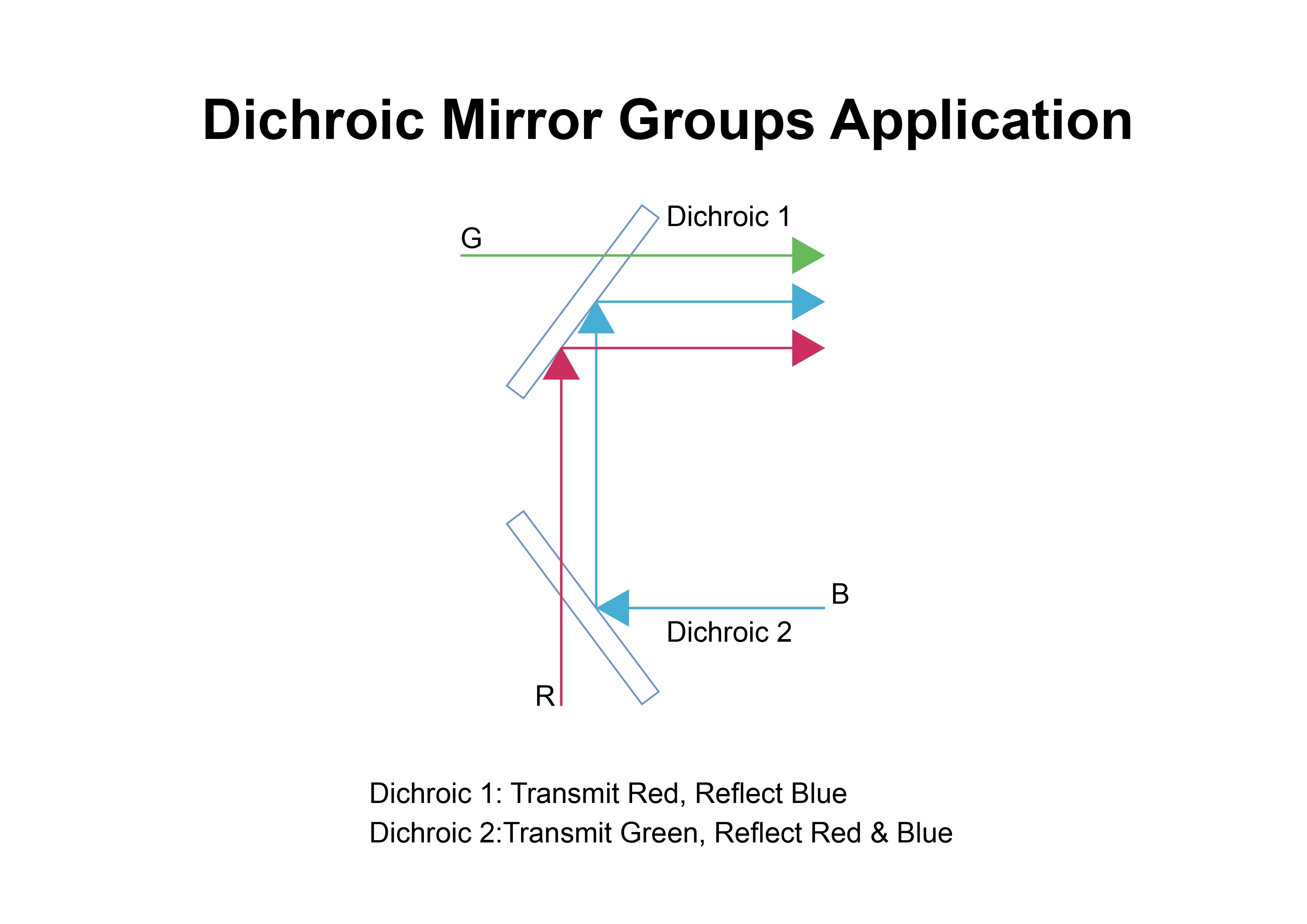

Dichroic mirrors have important applications in the filtering of spectral components, in splitting or combining two beams that have different wavelengths, and in fluorescence microscopy.

While an ordinary beamsplitter causes a loss of intensity, a dichroic mirror can split a beam into two parts of different wavelength without any appreciable loss of intensity. This makes it very useful for many different purposes.

For instance, in fluorescence microscopy, a dichroic mirror is used to separate the fluorescence light, with critical image information, from the residual pump light.

At Shanghai Optics, we manufacture custom mirrors per your specifications. Please contact us to discuss your custom order.

Factory Standards:

Coating

Contact us today for assistance with your custom optics project.