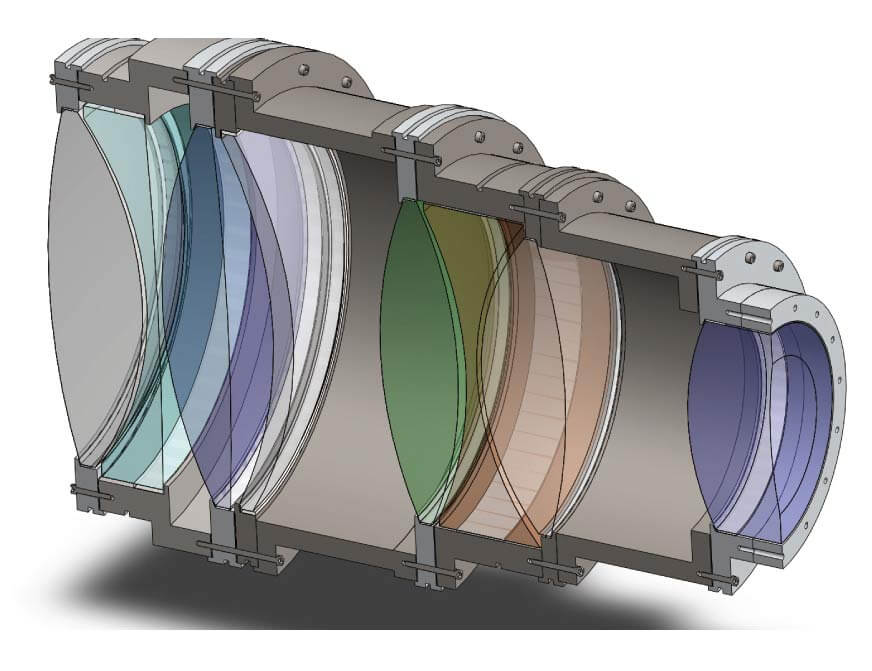

An opto-mechanical engineer does more than just provide a holder or mount for optical components. Improper mounting can cause stresses or distortions on component surfaces, degrading system performance under operating environment conditions. With over 60 years of experience in designing and manufacturing opto-mechanical products, Shanghai Optics offers cost-effective solutions and fast delivery services. Our Optomechanical engineering design experience and streamlined production methods enable us to create highly efficient design and production processes. Compared to other optical manufacturers, we offer:

Members of our closely integrated design and production teams use their specialized skills and experience to create customized optical instruments, assemblies, and optical systems. They design and execute plans from initial concept and prototyping to final product manufacture. Each opto-mechanical design is created by:

Our experience in designing high-precision optical instruments can help you quickly deliver high-quality products at a lower cost.

Our tightly integrated teams of optical design and mechanical engineers employ the following techniques:

By adhering to these design practices and MIL standards, we produce high-precision optical instruments that are both durable and cost-effective, consistently delivering exceptional performance.

For mechanical parts (housings, spacers, retainers, etc.), engineers must carefully select materials, such as metals, considering factors like weight, durability, cost, and stability. Selecting the appropriate material or metal is crucial for ensuring the optimal performance of both the mechanical and optical components within opto-mechanical systems.

We offer mechanical components crafted from a diverse selection of metals, including:

Discover how our opto-mechanical design services can help you save time, effort, and costs when building high-precision optical lenses and assemblies. Contact our sales engineers today at 732-321-6915 or email us at rfq@shanghai-optics.com. Or visit “Build Your Own Lens” to start your design process today!