Posted on: Friday, August 12th, 2022 In: Learning Optics with Austin

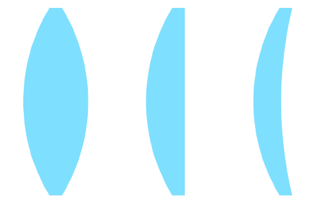

We briefly discussed spherical and aspherical lenses in “Intro to Optical Components”. Spherical lenses can further be broken down into different categories. Plano convex lenses are flat on one side while spherical on the other. Biconvex lenses are spherical on both sides. Similarly, for concave lenses, plano concave lenses are flat on one side and concave on the other. Biconcave lenses are… you guessed it- concave on both sides. Finally, there are meniscus lenses which do not have a flat surface. This is a more in-depth discussion of convex and concave lenses that began in “Intro to Optical Components.”

biconvex, plano convex and meniscus convex, respectively

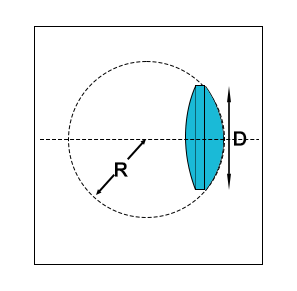

Shape is but one way of describing spherical lenses. Quantitative descriptions of lenses include radius, diameter, thickness, focal length, surface flatness, clear aperture, and surface quality. While one might think that the lens diameter is merely double the lens radius, this is not the case for lenses. The radius is the distance from the surface of the lens to the center of curvature. The diameter on the other hand is the width of the lens from top to bottom. Thickness has two main measures: thickness of center (TC) and thickness of edge (TE). The radius, diameter, thickness, and focal length are given an error bound (+/-) of a certain amount to indicate the tolerance of the lens.

Radius vs. Diameter of Lens (R=radius, D=diameter)

For example, a customer wants a lens with a diameter of 150 mm. While the requirements are clear on paper, it is impossible to craft a lens to the exact specifications due to manufacturing limitations and accuracy. Thus, there might be a tolerance of +/- 0.05 mm so that the final product has a diameter in the range of 149.05 mm and 150.05 mm. Of course, a lens with a diameter tolerance of +/- 0.01 mm would be more expensive than a lens with a diameter tolerance of +/- 0.05 mm as more accuracy is needed and thus the difficulty of manufacturing the lens. In the next post, we will discuss the remaining 3 quantitative descriptions: surface flatness, clear aperture, and surface quality.