Posted on: Monday, August 29th, 2022 In: Learning Optics with Austin

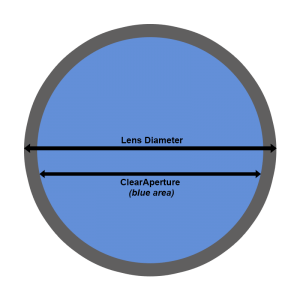

In theory, the entire lens would be up to the qualifications set by the customer. After all, if a customer ordered a 150mm lens, the whole 150mm lens should be up to specification… right? Wrong. This is because in the real world, nothing can be manufactured precisely as specified. While on paper the entire lens works, in reality, the edges of the lens are not to specifications. To account for this error, clear aperture is the area of the lens that is up to specification. Usually, it is written as a percentage of the lens (such as > 95%) or an amount such as 145mm.

Surface quality quantifies the irregularities of the lens surface. We do not want the lens surface to look like the surface of the moon with various spots and streaks and craters. To quantify the smoothness of the lens, scratch measures the size of streaks across a lens. The thicker the cut, the higher the scratch quantity. Similarly, the dig measures the size of spots or bubbles in the lens. The greater the crater or bubble, the higher the dig quantity. Normally, the scratch is greater than the dig.

Surface flatness measures how close the lens surface is to its specifications. The ideal measurement would be 0 which means the manufactured lens is exactly to specifications as the lens on paper. As with clear aperture however, nothing is perfect and thus the product will deviate from the plan. Surface flatness is measured at a certain wavelength in waves (λ) with values closer to 0 being the best and larger values having greater deviations. For example, λ/4 at 400nm would be better than λ/2 at 400nm.