Overcoming Challenges in Freeform Optics: From Design to Scalable Manufacturing

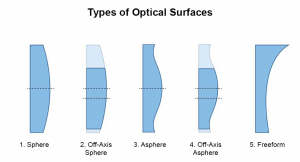

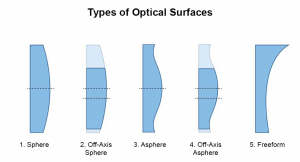

Freeform optics are advanced, custom-designed components with non-rotationally symmetric surfaces. Unlike traditional spherical or aspheric lenses, freeform surfaces enable precise light control, reduced weight and size, and superior performance in compact optical systems. From augmented reality to aerospace, the demand for freeform optics is growing—but so are the technical challenges.

Below, we explore key fabrication challenges and solutions across six critical domains.

1. Complex Freeform Optics Design

Designing freeform optics requires overcoming both software and computational limitations:

- Software Constraints: Most optical design tools are optimized for symmetric systems. Freeform geometries require enhanced features for ray tracing, wavefront analysis, and system optimization, which many standard tools still lack.

- High Computational Load: Optimization techniques—such as genetic algorithms and non-sequential ray tracing—are essential but computationally intensive, often requiring specialized hardware and software.

- Tolerance Sensitivity: Freeform designs are highly sensitive to small deviations. Tight alignment and manufacturing tolerances demand advanced modeling and error analysis.

2. Precision Manufacturing of Freeform Optics

Manufacturing freeform surfaces introduces a new level of complexity:

- Diamond Turning Limitations: Precision diamond turning is effective but difficult for non-symmetric shapes, where tool path errors can reduce optical quality.

- Advanced Polishing Techniques: Conventional polishing methods are insufficient. Technologies like Magnetorheological Finishing (MRF) and ion-beam figuring enable high-precision results but are slow, costly, and operator-dependent.

- Replication Constraints: Mass-production methods like injection molding can replicate freeform shapes but face challenges in material selection, surface accuracy, and defect rates.

3. Metrology and Quality Assurance

Inspection and quality control are significantly more difficult for freeform optics:

- Non-Standard Measurement Tools: Traditional interferometers struggle with freeform geometries. Optical Coordinate Measuring Machines (CMMs), 3D profilometers, and wavefront sensors are often needed and must be custom-configured.

- Complex Error Mapping: Surface form error, slope error, and residual aberrations vary across non-uniform geometries, complicating both inspection and correction.

- Alignment Sensitivity: Integrating freeform optics into a system demands precision alignment tools. Even minor misalignments introduce significant optical errors.

4. Cost and Scalability Considerations

High customization comes with high cost:

- Prototyping Expenses: Specialized machinery and labor increase the cost of prototyping, with extended design cycles compared to traditional lenses.

- Lack of Standardization: Each freeform design typically requires a unique manufacturing process, limiting mass production potential and driving up unit costs.

- Tool Wear: Machining freeform surfaces accelerates wear on diamond tools, increasing downtime and cost for recalibration or replacement.

5. Assembly and System Integration

Freeform optics must be precisely integrated for full performance:

- Complex Assembly Protocols: Mounting multiple freeform components in a single system often requires real-time alignment tools and custom fixtures

- Aberration Risk: Since many freeform optics are designed to correct system-level aberrations, misalignment can severely degrade performance or create new errors.

- Thermal and Mechanical Stress: Operational stresses (e.g., vibration, temperature change) require robust mounting strategies and materials with low thermal expansion coefficients.

6. Material and Coating Challenges

Not all optical materials are ideal for freeform geometries:

- Material Suitability: Some optical materials cannot be machined into freeform shapes due to brittleness, thermal sensitivity, or polishing limitations.

- Environmental Requirements: Applications in aerospace or underwater imaging require materials resistant to radiation, humidity, and temperature variation.

- Coating Uniformity: Applying AR or protective coatings on freeform surfaces presents technical challenges due to their irregular geometries, affecting both performance and durability.

The Future of Freeform Optics Fabrication

Despite the challenges, freeform optics continue to push the boundaries of optical innovation. With ongoing advancements in design software, fabrication technology, and metrology, freeform optics are rapidly becoming viable for broader commercial use.

From custom sensor solutions to next-gen wearable displays, mastering the fabrication of freeform optics will define the next chapter of precision photonics.