Introduction

Shanghai Optics has become a trusted leader in designing and manufacturing high-resolution microscope objectives. Our product line spans from conventional 2X to 100X flat-field objectives to advanced metachromatic designs. This article outlines the full manufacturing workflow of a precision 20X microscope objective, demonstrating the technical rigor behind every stage of production.

Optical Design

The process begins with defining customer needs and translating them into precise optical requirements.

- Requirement Analysis – Engineers examine application demands, lens specifications, and acceptance criteria.

- Design and Simulation – Using advanced software such as ZEMAX, the optical system is modeled, refined, and optimized for performance.

- Tolerance Analysis – Engineers establish component tolerances to ensure manufacturability without compromising resolution.

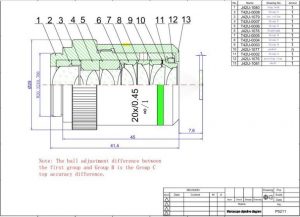

- Engineering Drawings – Each optical element is documented through detailed drawings that guide downstream fabrication.

Structural (Mechanical) Design

While optical modeling is underway, structural engineers develop the housing and support system.

- Mechanical Requirements – The external dimensions, threads, and interface standards are specified to match customer systems.

- Manufacturing Constraints – Materials, surface treatments, and tolerance limits are chosen to support repeatable production.

- Engineering Drawings – Comprehensive CAD models and drawings are created for machining and assembly.

Lens Processing

Producing the optical core involves multiple precision steps.

- Process Planning – Engineers define manufacturing sequences, tooling, and tolerances.

- Material Preparation – Optical glass is cut into blanks.

- Grinding

- Coarse Grinding: Shapes the raw blank.

- Fine Grinding: Refines curvature and thickness with high precision.

- Polishing – Surfaces are polished to optical smoothness using classical and advanced methods.

- Edging – The lens diameter is ground to final specifications.

- Inspection – Interferometers, projectors, micrometers, and calipers verify shape and finish.

- Cleaning – Ultrasonic cleaning ensures particle-free surfaces.

- Coating – Vacuum deposition applies anti-reflective or spectral coatings.

- Cementing – Multiple lens elements are bonded with UV adhesives and aligned precisely.

- Blackening – Lens edges are inked to suppress stray light.

- Final Inspection – Surface quality and dimensions are verified before controlled storage.

Mechanical Parts Fabrication

The objective housing and components require equally rigorous processing.

- Process Planning – Machining steps and tooling are defined.

- Material Preparation – Metals are cut to blanks.

- Machining – CNC lathes, milling machines, and other precision tools shape components.

- Inspection – Coordinate measuring machines (CMMs) confirm dimensional accuracy.

- Surface Treatments – Anodizing, sandblasting, or plating protect and finish surfaces.

- Final Inspection and Storage – Cleanroom handling ensures readiness for assembly.

Lens Group Assembly

Once parts are fabricated, the optical groups are assembled.

- Point Glue Repair – Individual lenses are aligned and fixed with UV adhesives.

- Optical Axis Turning – Precision machining ensures concentricity and alignment.

Final Assembly and Adjustment

The complete objective is assembled, tested, and adjusted to reach its design performance.

- Lens Installation – Elements are installed in mechanical housings.

- Debugging – Star target observation is used to detect aberrations and refine alignment.

- Resolution Testing – Resolution targets confirm optical performance.

- Focal Length Adjustment – Precision machining ensures correct working distance.

Quality Control and Packaging

Before shipment, every objective undergoes extensive inspection.

- Re-inspection – Star target tests and MTF (modulation transfer function) analysis validate performance.

- Packaging – Objectives are sealed in protective bottles and cartons under controlled conditions.

Conclusion

The manufacturing of high-resolution microscope objectives demands integration of optical design, advanced machining, and careful assembly. Each stage, from simulation to packaging, reflects Shanghai Optics’ commitment to precision and quality. The 20X objective exemplifies how engineering expertise and strict process control yield instruments capable of meeting the most demanding research and industrial applications.

Relevant Materials

https://www.shanghai-optics.com/about-us/resources/technical-articles/choosing-the-right-microscope-types-for-your-needs/

https://www.shanghai-optics.com/about-us/resources/technical-articles/exploring-the-functionality-of-microscope-lenses/

https://www.shanghai-optics.com/about-us/resources/technical-articles/conjugate-long-working-distance-microscope-objectives/

https://www.shanghai-optics.com/about-us/resources/technical-articles/precision-microscope-objective-manufacturing/