Producing top-tier microscope objectives is a highly specialized craft, and Shanghai Optics has honed this expertise. Our journey involves a blend of advanced technological know-how and a deep understanding of precision manufacturing. We create a wide array of objectives, from standard magnifications like 2X to 100X, to highly specialized ones such as 1X, 3X, or even 133X. Our focus is on objectives that provide exceptional clarity and minimal color distortion, including flat-field achromatic, semi-apochromatic, and apochromatic designs. For the most demanding applications, our super-apochromatic objectives deliver unparalleled image fidelity, largely due to their superior chromatic aberration correction. Our dedication to optical innovation, combined with rigorous quality control and meticulous mechanical engineering, has cemented our position as a leader in high-performance microscope objective design and production.

Crafting a microscope objective is a multifaceted process, beginning long before any glass is cut.

It all starts with understanding the need. We work closely with clients and industry experts across various fields, from life sciences to industrial inspection, to pinpoint specific requirements. What level of resolution is needed? Are there special spectral requirements, like for fluorescence or infrared microscopy? These questions lay the groundwork. Our R&D team then takes these defined needs and translates them into a detailed design plan. This involves considering the optical architecture, selecting appropriate materials, and outlining the production roadmap. Multiple rounds of technical reviews and optimizations ensure the plan is robust and feasible.

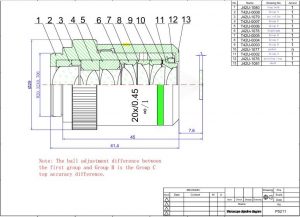

With a solidified plan, our optical engineers get to work defining the critical parameters: magnification, numerical aperture (NA), working distance, and field flatness—all meticulously tailored to the application. Our reputation for exceptional chromatic and spherical aberration correction is a result of using advanced optical design software, such as Zemax and Code V. These tools allow us to precisely optimize lens shapes, material pairings, and alignments to achieve stringent aberration control. For our high-end objectives, super-apochromatic designs are key to maximizing imaging fidelity. Before any physical production begins, extensive simulations are run to validate the design’s viability and set precise tolerance levels for every attribute, from lens curvature to thickness and alignment, guaranteeing consistent quality in mass production. The culmination of this stage is a comprehensive set of engineering drawings and detailed design documentation, serving as the definitive guide for production and quality control.

Once the digital design is perfect, the physical creation process begins.

Just as crucial as the optics is the housing that holds them. Our mechanical engineering team designs precision lens barrels to ensure lenses are positioned accurately and the optical axis remains perfectly aligned. Considerations extend to thermal stability, mechanical resilience, and user ergonomics. For the barrel materials, we select high-grade aluminum alloys or stainless steel, chosen for their strength and durability. Specialized surface treatments like anodizing and blackening are then applied to enhance longevity and minimize unwanted internal reflections. For demanding environments, we even use materials with enhanced heat and radiation resistance.

This is where raw materials transform into highly refined optical elements. Utilizing advanced optical fabrication equipment, including CNC grinders and polishers, we achieve nanometer-level precision in surface quality. Each lens is meticulously crafted to meet stringent design specifications. Following polishing, every lens undergoes interferometric testing to validate surface accuracy and ensure it’s free from defects, maintaining strict control over wavefront errors, especially at high magnifications.

Next come the advanced coating techniques. Through state-of-the-art multilayer coating processes, we maximize light transmission while minimizing dispersion and reflections. The type of coating varies based on the application, ranging from anti-reflective to fluorescence-optimized or even corrosion-resistant treatments. Each coating is rigorously inspected for uniformity and endurance.

Finally, the lenses are precisely adhered. Technicians apply UV-curable adhesive to designated surfaces, and the lenses are meticulously aligned and bonded using a centering instrument to ensure precise eccentricity adjustment. After alignment confirmation, the assembled lenses are placed in a UV curing chamber for 12 hours for optimal adhesion. To reduce stray light interference, the measurement surface of the lens is treated with a black coating, enhancing overall optical efficiency.

The final stages involve bringing all the components together and ensuring flawless performance.

Using CNC machining, lens barrels are fabricated to exacting specifications, enabling accurate alignment and smooth operation. These barrels then undergo surface finishing treatments such as anodizing or blackening to further reduce internal reflections and bolster durability. For challenging environments, additional treatments are applied for increased corrosion and wear resistance.

Objectives are assembled in a controlled cleanroom environment to mitigate contamination risks. Strict protocols are followed to maintain specific lens distances and angles, crucial for optimal performance. Using laser interferometers, technicians perform high-precision optical axis alignment, ensuring each objective meets exacting standards. Any deviations are meticulously adjusted to prevent image degradation. Each objective then undergoes exhaustive functional testing to confirm focal length accuracy, field flatness, and chromatic aberration correction, with fine adjustments made as needed to meet performance expectations.

Before leaving our facility, every objective faces rigorous quality checks. Modulation Transfer Function (MTF) testing evaluates image resolution and contrast across varying spatial frequencies, verifying adherence to our stringent quality criteria. Objectives are also subjected to environmental reliability testing under simulated conditions to assess performance across different temperatures, humidity levels, and mechanical stresses, ensuring stability and resilience. The final step is a thorough aesthetic and functional inspection to confirm the objective is free from any defects, accompanied by a comprehensive quality inspection report and certification.

The final objectives are meticulously cleaned and packaged in dustproof, anti-static materials to ensure safe transport and storage. Each package includes a comprehensive user manual, quality certificate, and warranty documentation, reinforcing client confidence and satisfaction.

At Shanghai Optics, our meticulous production stages result in microscope objectives that deliver unmatched resolution, chromatic aberration correction, and light transmission. They are designed for remarkable stability, reliability, and durability, consistently meeting the stringent demands of advanced research, clinical, and industrial applications. Our commitment to excellence, from initial design to final packaging, ensures that each objective provides outstanding imaging quality and performance, making Shanghai Optics a trusted partner in precision optics.